Products

Index > Products > Customized products > One-position Light Vertical Machine Tool

One-position Light Vertical Machine Tool

Interested In This Machine?REQUEST A QUOTE

Quick Details

Workpiece length: 100 ~ 500 mm

Turning diameter: 10 ~ 300 mm

One-position structure features:

a. Precision linear guide oriented

b. CNC lifting, rotating frequency conversion.

c. Sheet metal shield shell with sliding door

d. Standard two-dimensional fine-tuning of inductor

e. Main lifting gear has two kinds of structure:counterweight and without counterweight, selected according to the requirements of customersWorkpiece length: 100 ~ 500 mm

Turning diameter: 10 ~ 300 mm

One-position structure features:

a. Precision linear guide oriented

b. CNC lifting, rotating frequency conversion.

c. Sheet metal shield shell with sliding door

d. Standard two-dimensional fine-tuning of inductor

e. Main lifting gear has two kinds of structure:counterweight and without counterweight, selected according to the requirements of customers

Turning diameter: 10 ~ 300 mm

One-position structure features:

a. Precision linear guide oriented

b. CNC lifting, rotating frequency conversion.

c. Sheet metal shield shell with sliding door

d. Standard two-dimensional fine-tuning of inductor

e. Main lifting gear has two kinds of structure:counterweight and without counterweight, selected according to the requirements of customersWorkpiece length: 100 ~ 500 mm

Turning diameter: 10 ~ 300 mm

One-position structure features:

a. Precision linear guide oriented

b. CNC lifting, rotating frequency conversion.

c. Sheet metal shield shell with sliding door

d. Standard two-dimensional fine-tuning of inductor

e. Main lifting gear has two kinds of structure:counterweight and without counterweight, selected according to the requirements of customers

Quick Details

-

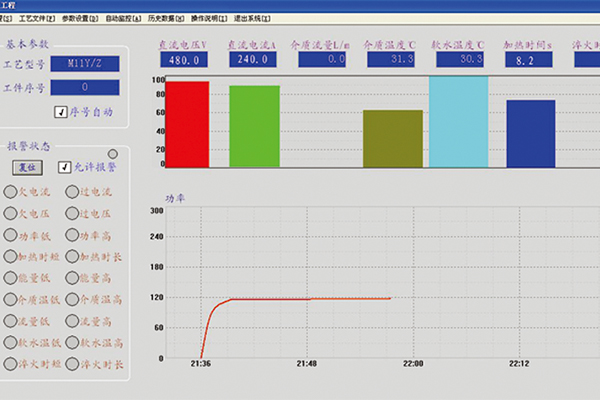

Energy monitor consisted with advanced industrial computer , high speed data acquisition and processing cards, etc. Has a perfect process channel for collecting all kinds of signals, and completes the testing data input and control information output;Through rapid response the interrupt request in the process of production, exchange information with production process in real time.

Through signal acquisition system, signal processing, signal feedback system, Energy monitor do real-time monitoring of heat treatment energy output power (KWS), voltage, current, frequency, power, and the temperature of quenching medium, flow and heating time, cooling time and other various parameters may affect the heat treatment process. Compare with the preseted standard data real-time to judge if processing workpiece(s) is(are) qualified or not, timely alarm when workpiece unqualified, in order to ensure that equipment can get qualified quenching quality under different work conditions

Products Specification

Service

-

Training and Use

We will supply friendly English operation manual and installation. Customer is warmly welcomed to visit our factory for free training. We can also send engineer to customer’s country to supply training.

-

Guarantee & After-sale Service

We supply one year warranty under normal use and lifetime technical support.We can provide engineers overseas training.

-

Payment Terms

1.T/T in advance;

2.West Union: we can accept small payment(below $3000), but the banking charges shall be paid by the buyer;

3.L/C is acceptable if the amount is big. Please issue the L/C draft for our confirmation

-

Documents after shipment

We will send original documents to you by DHL, including Packing List, Commercial Invoice, Sales Confirmation, Bill of Lading, and other certificates as required by customer.

Related Products

Send Inquiry/ message to us

*

*

*